Products

- Water Treatment[26]

- Filters[2]

- Ceramics[36]

- Catalyst[6]

- Carbon[53]

- Wiring Ducts[1]

- Refrigeration & Heat Exchange Parts[5]

- Separation Equipment[2]

- Chemical Process Equipment Parts[10]

- Pressure Vessels[1]

- Gas Disposal[2]

- Other Refrigeration & Heat Exchange Equipment[1]

- Chemical Auxiliary Agent[10]

- Other Metals & Metal Products[10]

- Oxide[6]

- Abrasives[1]

- Chemical Transportation Equipment[4]

- Other Industrial Filtration Equipment[10]

- Other Lights & Lighting Products[2]

- Other Filter Supplies[1]

- Inverters & Converters[1]

Contact Us

- Contact Person : Mr. Yang Jacky

- Company Name : Pingxiang Naike Chemical Industry Equipment Packing Co., Ltd.

- Tel : 86-799-3673812

- Fax : 86-799-3673808

- Address : Jiangxi,pingxiang,Penggao Industrial Park,Pingxiang City,Jiangxi Province,P.R.China

- Country/Region : China

- Zip : 337000

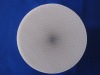

ceramic saddle intalox

Product Detailed

Related Categories:Ceramics

Detailed Product Description

Ceramic Saddles(Intalox)Ceramic saddles (intalox) are divided into two different types of products according to their properties, one is often used in the field of Chemical and Petrochemical industries, another is mainly used in environmental areas such as RTO(Regenerative Thermal Oxidizers) equipments. But both of them are the most frequently used high-performance packing and exhibit advantages for most applications in comparison with other shapes. Their smooth surface imparts a high chemical resistance and provides Ceramic Intalox saddle rings (Ceramic Saddles ) with a high level of stability. Due to their simple form, ceramic saddles can be produced at a relatively low cost.

Chemical composition:

SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O+Na2O | Other |

>73% | 17-25% | <1.0% | <0.5% | <0.5% | 2-4% | <0.1% |

Physical properties:

| Nominal size(inch) | 3/8'' | 1/2'' | 5/8'' | 3/4'' | 1'' | 1.5'' | 2'' | 3'' |

| Width(mm) | 8 | 10 | 12 | 14 | 21 | 30 | 40 | 57 |

| Height(mm) | 8 | 10 | 12 | 14 | 19 | 30 | 40 | 57 |

| Length(mm) | 16 | 20 | 24 | 28 | 38 | 60 | 80 | 114 |

| Thickness(mm) | 2 | 2.5 | 2.5 | 3 | 4 | 4.5 | 5.5 | 9 |

| Number per m3 | 1560K | 610K | 269K | 146K | 59K | 19680 | 8243 | 2400 |

| Remarks | K represents 1000 pieces | |||||||

| Package density (kg/m3) | 900 | 780 | 700 | 670 | 650 | 580 | 550 | 530 |

| Free volume (%) | 63 | 68 | 71 | 75 | 77 | 80 | 79 | 75 |

| Surface area (m2/m3) | 825 | 647 | 535 | 350 | 254 | 180 | 120 | 91 |

| Specific gravity (g/cm3) | 2.25~2.35 | |||||||

| Water absorption(%) | <0.3 | |||||||

| Acid resistance (%) | >99.6 | |||||||

| Max operating temp. | 1100 | |||||||

| Porosity (%) | <1 | |||||||

| Mohs hardness (scale) | >6.5 | |||||||

| Thermal conductivity(w/m.k) | 0.9-1.0 | |||||||

| Specific heat (j/kg) | 850-900 | |||||||

The drawing:

Dimension:

| Nominal Size | Alias DN | Diameter of Deck D | Outside Diameter L | Height H | Wall thickness T | Width W |

| 3/8'' | 10 | 10±2.0 | 16±2.0 | 8±2.0 | 1.5±1.0 | 8±2.0 |

| 1/2'' | 12 | 12±1.0 | 20±1.4 | 10±1.0 | 2.0±1.0 | 10±2.0 |

| 5/8'' | 16 | 16±2.0 | 24±1.5 | 12±1.0 | 2.0±1.0 | 12±2.0 |

| 3/4'' | 19 | 19±5.0 | 28±5.0 | 20±3.0 | 3.0±1.0 | 20±3.0 |

| 1'' | 25 | 25±4.0 | 38±4.0 | 22±3.0 | 3.5±1.0 | 22±2.0 |

| 1.5'' | 38 | 38±4.0 | 60±4.0 | 35±5.0 | 4.0±1.5 | 35±5.0 |

| 2'' | 50 | 50±6.0 | 80±6.0 | 48±5.0 | 5.0±1.5 | 40±4.0 |

| 3'' | 76 | 76±8.0 | 114±8.0 | 60±6.0 | 9.0±1.5 | 60±6.0 |

Other products