- Water Treatment[26]

- Filters[2]

- Ceramics[36]

- Catalyst[6]

- Carbon[53]

- Wiring Ducts[1]

- Refrigeration & Heat Exchange Parts[5]

- Separation Equipment[2]

- Chemical Process Equipment Parts[10]

- Pressure Vessels[1]

- Gas Disposal[2]

- Other Refrigeration & Heat Exchange Equipment[1]

- Chemical Auxiliary Agent[10]

- Other Metals & Metal Products[10]

- Oxide[6]

- Abrasives[1]

- Chemical Transportation Equipment[4]

- Other Industrial Filtration Equipment[10]

- Other Lights & Lighting Products[2]

- Other Filter Supplies[1]

- Inverters & Converters[1]

- Contact Person : Mr. Yang Jacky

- Company Name : Pingxiang Naike Chemical Industry Equipment Packing Co., Ltd.

- Tel : 86-799-3673812

- Fax : 86-799-3673808

- Address : Jiangxi,pingxiang,Penggao Industrial Park,Pingxiang City,Jiangxi Province,P.R.China

- Country/Region : China

- Zip : 337000

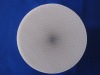

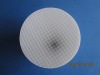

Honeycomb Ceramic Substrate (Cordierite)

Detailed Product Description

Introduction

The honeycomb ceramic substrate made of cordierite enjoys the merits of very low thermal expansion coefficient, high specific surface area, low pressure drop, rapid light-off and unique structures which are perfect for car catalytic converter.

We can supply both ceramic element coated with noble metals of Pt, Pd, Rh and ceramic element without noble metals. The shape will be round, oval or racetrack with 100 cpsi, 300 cpsi, 400 cpsi or 600 cpsi cells that provide high surface for the precious metal catalysts that convert noxious emission into water vapor, carbon dioxide and so on.

Specification (Catalyst carrier (straight hole) used in gasoline engine car)

Shape | Shape diameter ( mm ) | ||

Channel Density: 100-400 Holes/square inch | |||

Racetrack Shape (Ellipse) | 169*85.7*127 |

| 150*100 |

148*84*127 | 150*75 | ||

144.8*81*76.2 | 125*130 | ||

144.8*81.3*75 | 144*152 | ||

127*63.5*127 | 118*152 | ||

145*80*80 | 106*150 | ||

93*61*90 | 106*100 | ||

120.6*80*65 | 103*100 | ||

120*80*75 | 101.6*100 | ||

147*96*75 | 100*100 | ||

100*100*75 | 93*130 | ||

50*50*25 | 93*49.85 | ||

| 83*88 | ||

| 80*100 | ||

| 80*75 | ||

| 100*75 | ||

| 125*100 | ||

| 125*130 | ||

Remark: We can customize the product according to the user's requirement if the channel density is within 600 holes/square inch, the shape diameter within 150*150 mm, and the height within 200 mm,. | |||

Num | Item | Index | ||||||||

CFT-02(260channel) | CFT-03(300channel) | CFT-04/06(400/600channel) | ||||||||

1 | Bulk density Kg/cm3 | ≤0.70 | ||||||||

2 | Water adsorption % | 20-27 | ||||||||

3 | Resistance To normal Atmospheric temperature | X(parallel to channels) | ≥50 | ≥60 | ≥65 | |||||

Y(vertical to channels) | ≥160 | ≥180 | ≥200 | |||||||

4 | Coefficient of thermal expansion -1(20-800) | ≤1.50*10-6 | ||||||||

5 | Soften Temperature | 1450 | ||||||||

6 | Thermal stability 800 | ≥3 | ||||||||

7 | Specific surface area cm2/cm3 | ≥20 | ||||||||

8 | Chemical composition range % | Al2O3 | SiO2 | MgO | K.Na2O | Fe2O3 | Other | |||

31-34 | 48-51 | 12-14 | <1 | <0.5 | <1 | |||||

10 | Thermal conductivity 20-100 W/m.k | 1.5-2.5 | 1.4-2.0 | 1.5-2.5 | 1.3-1.5 | 1.5-2.3 | 1.0-1.2 | |||